3D Scanning and Reverse Engineering

OUR SERVICES

3D scanning is the best way to accurately capture the shape and design of an object.

Our MetraSCAN 3D optical CMM scanner is the fastest and most accurate 3D scanner and portable CMM for shop floor environments.

ADDITIONAL SERVICES

In addition to our world class scanning equipment, we have a full suite of services to support your product development goals. We can provide CAD drawings, build complex CAD modelling, modify product designs and complete the manufacturing process.

3D scanning is just the start of your product development journey. We are able to help you through the entirety of your product development process. Whatever your 3D Scanning or Reverse Engineering needs, we're here to help you.

Get in touch now to see how we can support your project.

3D Scanning and Reverse Engineering Process

The 3D scanning process allows data to be captured digitally without damaging the physical object being scanned. We can translate physical objects of any size into precise digital CAD models quickly and accurately.

Scan

To begin, we laser scan the components to produce a point cloud in 3D space capturing every detail of the object with our high accuracy scanner. Scan data is collected which builds a digital representation of the item. Our laser scanners capture tens of thousands of points per second and allow us to inspect parts quickly.

Post Processing

Scanning techniques cause unwanted artefacts such as noise, outliers, holes, or ghost geometry. These must all be removed to create a true scanned replica. In the Post-Processing stage, we manually fill holes, clean, align and merge scan data.

Build the CAD

We provide you with a comprehensive digital representation of your part. The CAD documents we create can be used for reverse engineering, quality inspection and prototyping. There are two options for building CAD data from the scan data. Either laying a surface over the scan mesh and building clean CAD surfaces for the components. We undertake whichever will deliver the best results for you. The scan data can be used in the Reverse Engineering process which analyses the structure, function and operation of a device orobject.

Whatever your 3D Scanning or Reverse Engineering needs, we're here to help you.

Get in touch now to see how we can support your project.

3D Scanning and Reverse Engineering Projects

Vintage Car Suspension

Few cars are cooler than this souped up 1976 Holden Torana LX SS. Our new and specialised 3d scanning equipment made light work of digitising the suspension system. We scanned it in its free and compressed states. With the scan data we created a detailed report dimensioning the suspension points for LVVTA certification.

Cornwall Park Benches

Cornwall Park's Campbell Crescent upgrade is a beautiful setting for a recent project of ours. The elegant park benches had design input from many sources. To assist the project manager with the design development process we created an initial silhouette for the bench ends, scaled them down and 3D printed them. Clay was added to the 3D printed parts which we styled into our interpretation of the customer's requirements. Our client was able to take these parts into a meeting with key decision makers who could discuss, sculpt and approve the design. We then 3D scanned the clay, scaled it up, resurfaced the scanned data to achieve a high-quality finish and ran FEA to test extreme load conditions. The parts were then cast and now sit on Campbell Cresent for you to enjoy.

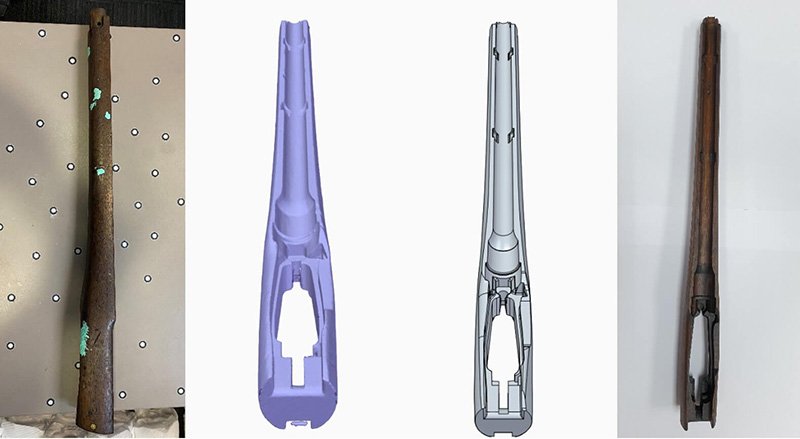

Gun Stock Restoration

A gun stock restoration specialist used our 3D scanning services to recreate gun stocks for historically significant guns. We scanned samples of original wooden stocks and provided our client with the data appropriate for CNC machining the parts. He has the parts machined and hand finishes them before sending the new gun stock to the gun owner. Below you can see the original gun stock, the scan image, the CAD file and the finished replica gun stock. It is rewarding to know we are supporting another Kiwi entrepreneur.